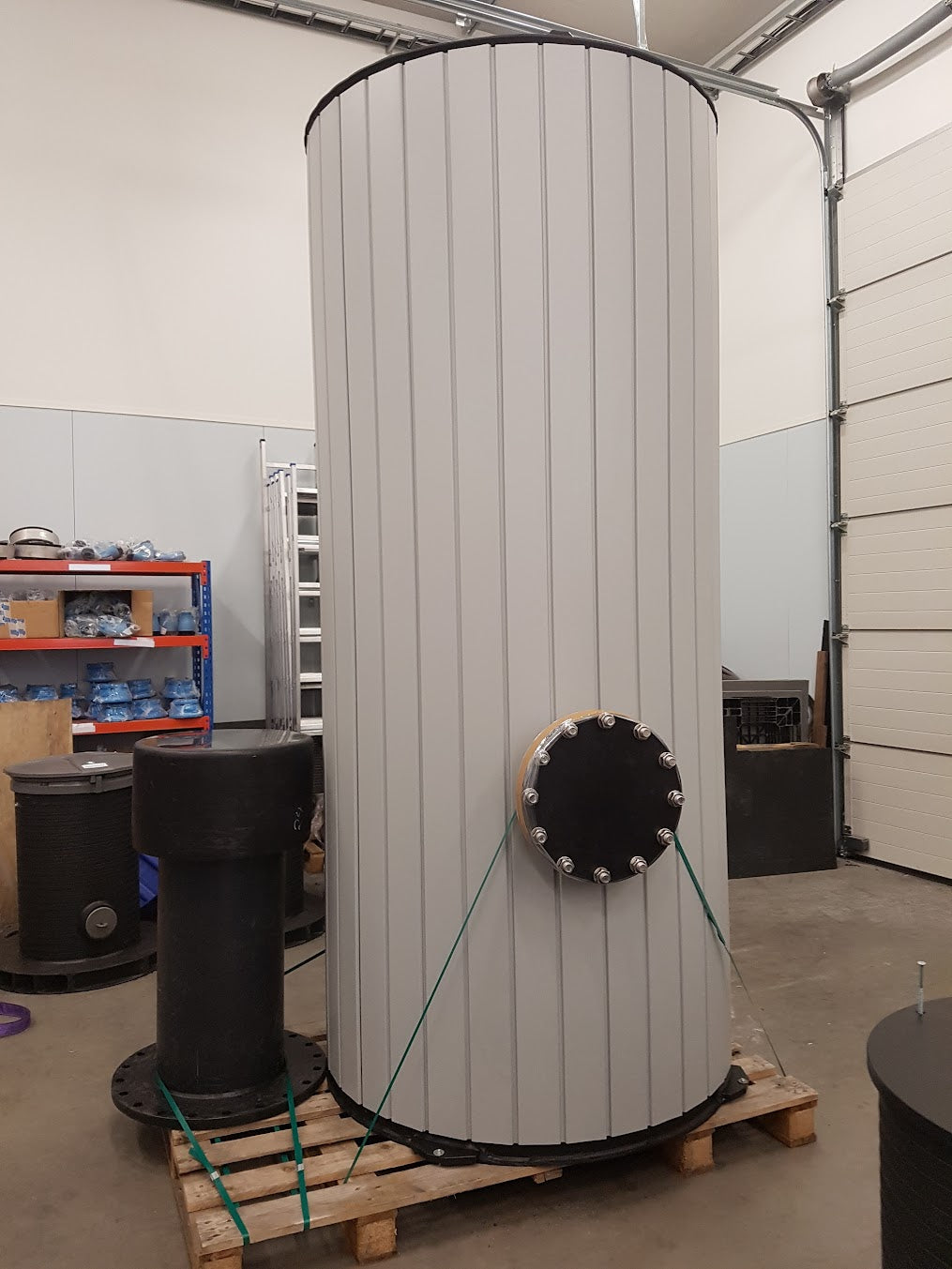

Water tanks

Water tanks also with integrated equipment space.

Device modes

Also rectangular equipment space solutions.

Active carbon filter

The tanks can also be lined with vinyl or sheet metal coating, and additionally insulated.

Kennolevy

Our high-quality honeycomb plate solution is integrated into the ends, bases and cover structures of the containers, offering durability even in the most demanding applications. This insulated sheet profile effectively utilizes the air inside it as insulation. The lightweight and rigid honeycomb panel is easy to install, and its transport to the place of use is cost-effective. We manufacture honeycomb panels in different strengths, up to 140 mm.

Robotic machining center

Our company's robotic machining center utilizes an ABB robotic arm for efficient hole-making and versatile piece processing for parts up to 4.5 meters in diameter.

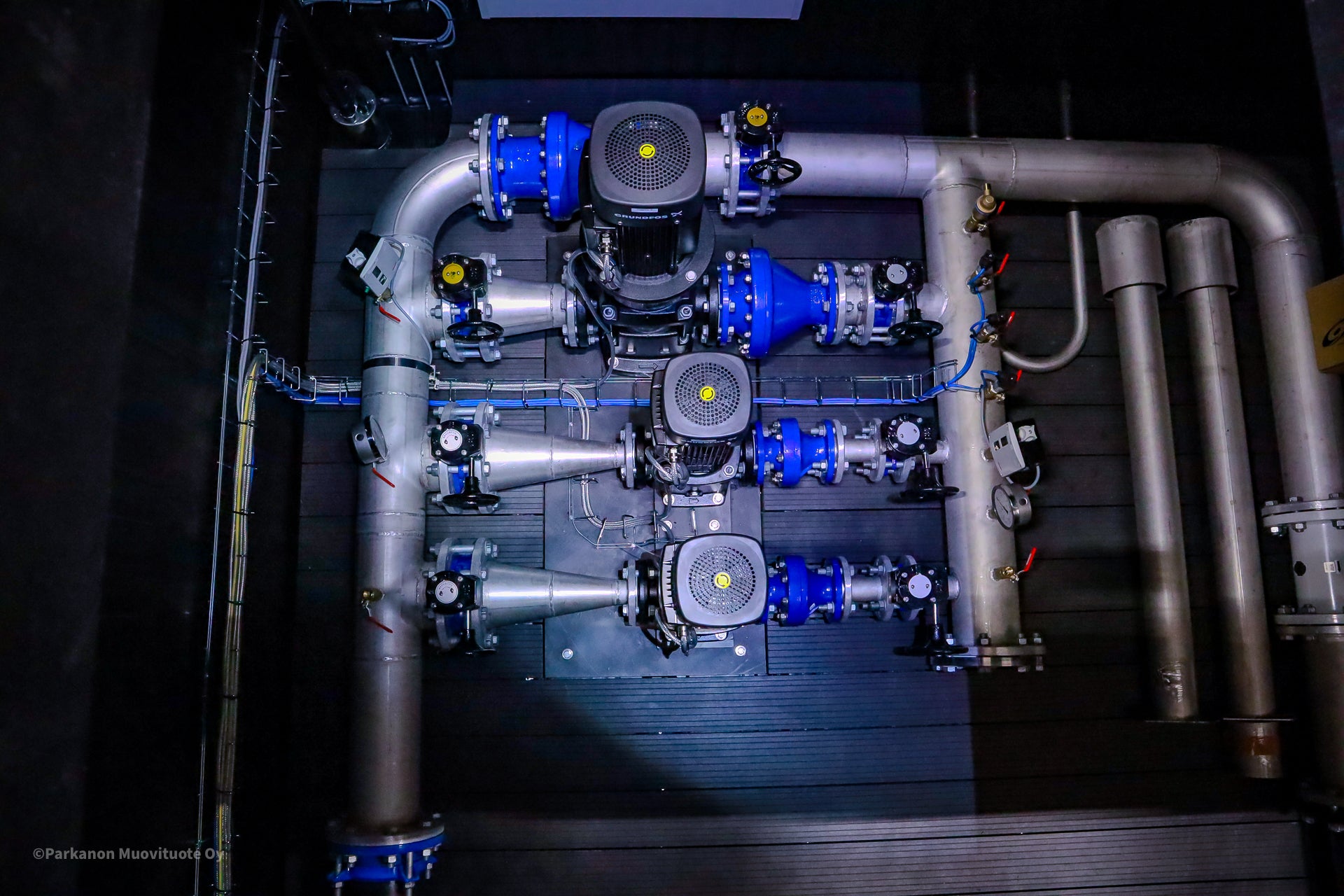

Ready-to-use units

We offer our customers top-class solutions where you can choose pre-installed piping, electrical installations and electrical equipment inside the plastic frame. This guarantees a fully functional entity that is ready for your use. In addition, we offer flexibility in selection, as you can choose either durable plastic or acid-resistant steel as the piping material, to best meet your needs and your operating environment.

Special applications and prototypes

We also design and manufacture special applications and individual prototype pieces.

Design

Our company not only operates as a manufacturer of plastic products, but also offers innovative 3D solutions and problem solving. We use our expertise to create unique and functional concepts for our customers' needs, be it product development, design or problem solving.

Frequently asked questions from us with answers:

Isn't steel more durable than plastic?

Especially in terms of chemical durability, plastic beats metals in most cases. The correctly chosen plastic quality can withstand acids, bases, solvents, moisture, weather changes, UV radiation or even all of these. For example, in pipeline applications, plastic withstands vibration and vibrates significantly better than traditional steel pipes.

What are the sliding properties of plastic?

Many plastic grades or mixtures have excellent sliding properties. They are wear-resistant and their coefficient of friction against, for example, steel is very low. Since no separate lubrication is needed, or water or another similar neutral substance can be used as a lubricant, plastics are suitable without problems for the food industry, the pharmaceutical industry, and the production of ultra-clean facilities and pipelines.

How long does a plastic pipe last?

A plastic pipe lasts up to 100 years.

What can you do with a plastic pipe?

Everything you can do with a steel pipe or concrete.

What is the environmental impact of a plastic pipe?

A plastic pipe has a lower environmental impact than a steel pipe or fiberglass solution and it can be completely recycled. In addition, its lifespan is up to 100 years.

How does Parkano Muovituote reduce the load on the environment?

We recycle all production waste and collect the waste heat generated in production for reuse. We are constantly exploring new opportunities to save nature in material selection, energy procurement, logistics, etc.

How big pipes can Parkano Muovituote produce?

We can manufacture pipes with a diameter of 3.5 meters. The maximum length is 45 meters.

Why is the factory located in Parkano?

Parkano's central location enables fast, cost-effective transport to the customer's destination. In addition, Parkano has a good supply of skilled labor.

How quickly can you deliver pumping stations?

We can deliver a basic pumping station in a few days and a special pumping station in an average of one month.

What advantages can you offer over your competitors?

Individual innovative solutions with high quality and reliable delivery.

To which municipalities have your large pumping stations been delivered?

Our area of operation is the whole of Finland.

How big are your big pumping stations?

The largest pumping stations have been 10 m high and over 3 m in diameter.

What types of plastic do you use in your products?

We use thermoplastics which are e.g. PE, PP, PLA and PVC. All the plastic grades we use are recyclable plastic that lasts up to 100 years. Most of the plastic grades are food grade. Some of our products are biodegradable.

What all does the robot do?

Our robot is suitable for plastic machining, where the accuracy and speed are top class. The robot works e.g. openings, cuts pipe ends and plates, and makes grooves, threads and turning pieces.